NEWS, EVENTS & BLOG

BLOG

Eight Steps to an Effective ESD Control Program

Press Office, VersaLogic Corporation, 07/15/20

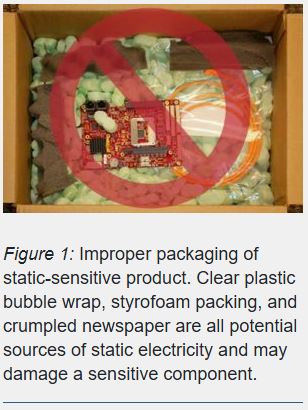

Electrostatic discharge, or ESD, is the sudden flow of electricity between two objects. ESD occurs after a buildup of static electricity on an object. Electrostatic charge is most commonly created by the contact and separation of two similar or dissimilar materials. For example, a person walking across the floor generates static electricity as shoe soles contact and then separate from the floor surface. An electronic device sliding into or out of a bag generates an electrostatic charge as the device makes multiple contacts and separations with the surface of the bag. As shown in Figure 1, even the seemingly inconsequential act of picking up a poly bag generates more than enough static electricity to cause shock and damage. That's why it's important to set up an effective ESD control program to eliminate the chance of damage. A complete electrostatic discharge prevention program includes a plan, training, protective equipment, management, and system audits. The following steps provide a framework for establishing an ESD control program: 1. Research and Consult with Experts Learn all you can about preventing ESD damage at your company. Check with industry groups such as the ESD Association (Rome, NY) and IPC Association (Northbrook, IL). Many engineering and consulting companies also provide specialized expertise. ESD safe product companies can provide good advice, but be aware that they can be biased. As a result, be sure to take your own measurements. See Figure 2 for some suggestions on where to start your research.

Electrostatic discharge, or ESD, is the sudden flow of electricity between two objects. ESD occurs after a buildup of static electricity on an object. Electrostatic charge is most commonly created by the contact and separation of two similar or dissimilar materials. For example, a person walking across the floor generates static electricity as shoe soles contact and then separate from the floor surface. An electronic device sliding into or out of a bag generates an electrostatic charge as the device makes multiple contacts and separations with the surface of the bag. As shown in Figure 1, even the seemingly inconsequential act of picking up a poly bag generates more than enough static electricity to cause shock and damage. That's why it's important to set up an effective ESD control program to eliminate the chance of damage. A complete electrostatic discharge prevention program includes a plan, training, protective equipment, management, and system audits. The following steps provide a framework for establishing an ESD control program: 1. Research and Consult with Experts Learn all you can about preventing ESD damage at your company. Check with industry groups such as the ESD Association (Rome, NY) and IPC Association (Northbrook, IL). Many engineering and consulting companies also provide specialized expertise. ESD safe product companies can provide good advice, but be aware that they can be biased. As a result, be sure to take your own measurements. See Figure 2 for some suggestions on where to start your research.

Figure 2: ESD Control Program Resources

- ESD Association www.esda.org

- IPC Association www.ipc.org

- ESD Products Manufacturers Talk to several vendors

- ESD training resources training.ipc.org/ (choose ESD Control under Electronics Assembly)

2. Identify Sensitive Work Areas Work areas requiring ESD protection include assembly and packaging stations, engineering and testing areas, and anywhere else that unshielded products or components are handled or stored (see Figure 3). To achieve the highest standards, include areas that are not always thought of as requiring ESD protection.

Figure 3: Typical Facility Areas Requiring ESD Protection

- Receiving

- Inspection

- Stores and warehouses

- Assembly

- Test and inspection

- Research and development

- Packaging

- Field service repair

- Offices and laboratories

- Clean rooms

3. Identify the Sources of ESD within Work Areas Non-conductive materials such as plastic parts, tape, cardboard and Styrofoam are common sources of ESD. High voltage items like computer monitors or laser printer paper also generate static charges. Measuring ESD levels with a static meter will show problem areas and items. 4. Establish the Level of Protection Required for Each Work Area Areas with high static generation may require special solutions, even when ESD-sensitive components are not handled directly. For instance, a plastic injection molding plant may have static levels high enough to require a wireless keyboard and mouse for each computer to prevent ESD damage from occurring through the I/O cables. 5. Develop a Plan The ESD Control Program Plan should include the tasks, activities and procedures necessary to adequately protect sensitive components and systems. Prepare written procedures and specifications that clearly communicate roles and responsibilities. The plan must include guidelines for personnel training, verification that the plan is being followed, and a list of the technical requirements and ESD protective products approved for use in the program.

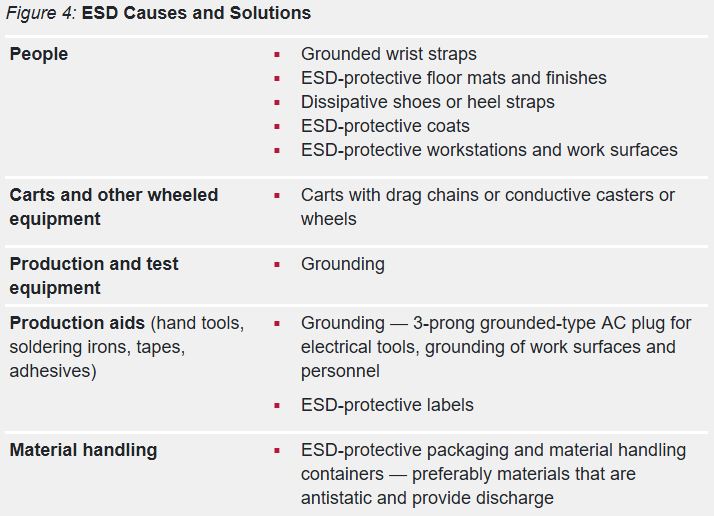

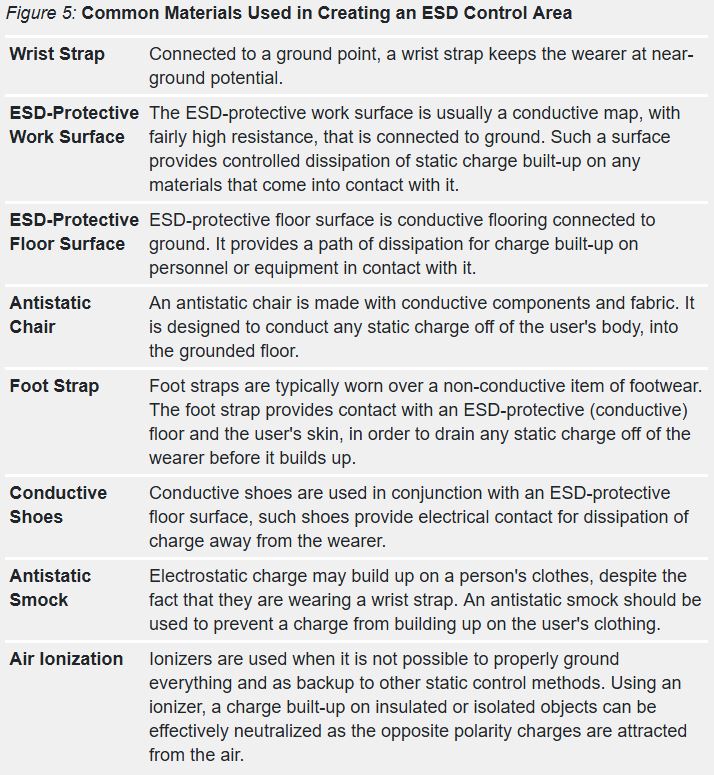

6. Institute Static Protection Solutions Protection methods include a combination of signage, grounding systems, and charge generation control. A well-protected area may be one in which grounding floor mats and work surface mats are installed, protected areas are marked with tape, and personnel wear wrist straps, heel straps and ESD protective clothing. See Figure 4, above, for additional static protection solutions and Figure 5, below, for common materials used in creating an ESD Control Area. Dry environments benefit from installation of ionization and humidification systems to reduce charge generation. ESD protection devices vary in capability, and the protective range should be checked against the sensitivity of the products being handled.

7. Build Teams and Educate Staff Enroll employees from relevant areas of the company to be team members. Make it their program, and delegate the responsibility of auditing and maintenance to them. Quality management can then verify records and conduct periodic compliance audits. Delegating in this way not only minimizes the drain on management resources, but also allows the affected employees to take ownership of the process, thus increasing employee participation and compliance. Train and retrain your personnel to instill a mindset that ESD awareness is a valuable ongoing effort that can mean the difference between the company's profitability and loss. Make sure that the program is understandable, even to non-technical employees. No ESD program will be completely successful without the complete participation of all staff. 8. Maintain the ESD Control System Protection of production floors, testing stations and other areas takes planning, education, maintenance, and testing. Ongoing maintenance and system audits are essential to ensure that ESD control programs remain effective. Many ESD devices lose effectiveness over time. Periodic cleaning keeps the equipment and devices working properly. Wrist straps, heel straps and other personal grounding devices require testing and occasional replacement. Periodic testing, either with static locators or grounding test equipment is needed to identify problems. A static charge meter can indicate the strength of the entire system. If an area is found to have minimal static charges, it is evidence of an effective system. Audit your plan to verify that the ESD control system is successful. Technological changes will dictate improvements and modifications. Provide feedback to management and employees. Adjust company practices to keep the program on track. To ensure ongoing compliance invest in quarterly ESD audits. Conclusion By shedding light on the hidden costs of electrostatic discharge, OEMs can learn to address this problem head-on. Although not readily apparent, the many hidden costs related to ESD are a significant drain on the financial wellbeing of many companies. It is critical that OEMs that handle electronic components keep a close watch on this issue. Through the development of effective ESD control processes and programs, OEMs can improve manufacturing yields, reduce field failures, lower warranty costs, and improve product reliability.